Optimal Timing for Backflow Testing

Backflow testing is essential for maintaining water safety and ensuring compliance with local regulations. The timing of these tests can impact their effectiveness and help prevent costly plumbing issues. Proper scheduling aligns with seasonal changes and plumbing system usage patterns.

Spring is a recommended time for backflow testing due to increased water usage and the need to prepare plumbing systems for the warmer months.

Fall testing helps identify issues before winter, when plumbing systems are more vulnerable to freezing and damage.

Testing immediately after installing or repairing backflow prevention devices ensures proper function and compliance.

Many jurisdictions require annual backflow testing to maintain water safety standards and prevent contamination.

Specialized tools used during backflow testing ensure accurate assessments of device functionality.

A technician conducts a backflow test to verify system integrity and compliance.

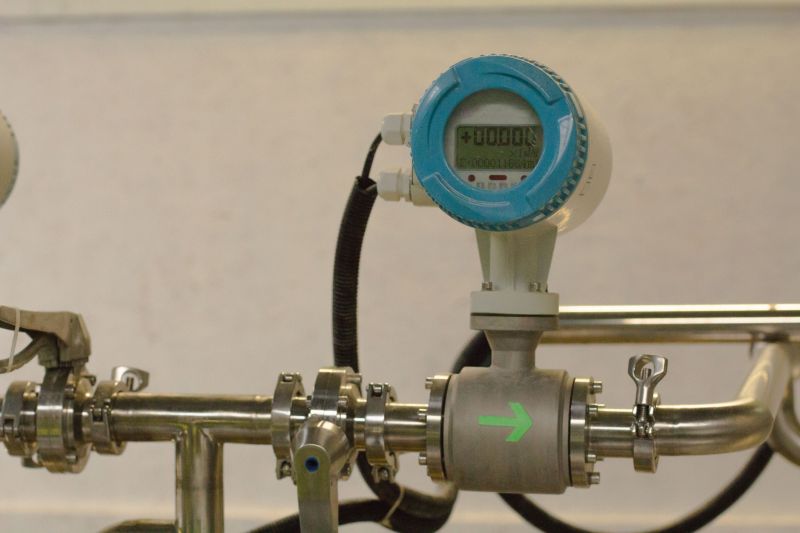

An installed backflow prevention device ready for testing.

Ways to make Backflow Testings work in tight or awkward layouts.

Popular materials for Backflow Testings and why they hold up over time.

Simple add-ons that improve Backflow Testings without blowing the budget.

| Season or Timing Factor | Recommended Action |

|---|---|

| Spring | Schedule testing to prepare for increased water use. |

| Fall | Perform testing before winter to prevent freezing issues. |

| Post-Installation | Test immediately after installation or repairs. |

| Annual | Ensure compliance with local regulations. |

| Weather Events | Test before extreme weather conditions. |

Backflow testing plays a critical role in safeguarding public water supplies. It involves checking backflow prevention devices to ensure they are functioning correctly and preventing contaminants from entering potable water systems. Regular testing can detect potential issues early, reducing the risk of water contamination and costly repairs. According to industry statistics, routine backflow testing can prevent thousands of contamination incidents annually, safeguarding health and maintaining system integrity.

A detailed view of the backflow testing procedure.

Tools used during backflow testing in action.

Maintaining backflow prevention devices to ensure reliability.

Monitoring water systems for backflow risks.

High-end options that actually feel worth it for Backflow Testings.

Finishes and colors that play nicely with Backflow Testings.

Little measurements that prevent headaches on Backflow Testings day.

A 60-second routine that keeps Backflow Testings looking new.

A frequent mistake in Backflow Testings and how to dodge it.

Small tweaks to make Backflow Testings safer and easier to use.

Lower-waste or water-saving choices for Backflow Testings.

The short, realistic tool list for quality Backflow Testings.

Interested in scheduling backflow testing? Filling out the contact form provides a convenient way to arrange inspections and ensure water safety compliance. Regular testing is vital for preventing water contamination and maintaining the integrity of plumbing systems. Early scheduling helps avoid penalties and costly repairs, making it a proactive approach to water system management.